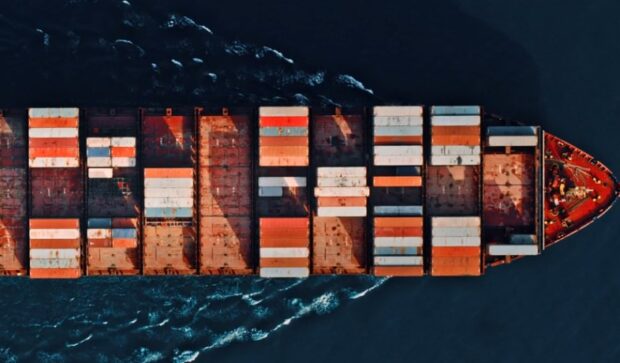

In heavy industry, the vendors you work with are more than suppliers – they’re strategic partners who shape the rhythm and reliability of your operations.

Whether you’re running a steel plant, managing a construction project, or overseeing a mining operation in a remote region, the vendors you bring in affect everything from cost control to worker safety.

The stakes are high. Equipment breakdowns, supply shortages, late deliveries, or subpar components can shut down entire lines, delay multimillion-dollar projects, or spark costly compliance violations.

That’s why vendor selection in sectors like manufacturing, energy, and construction isn’t just a box to check. It’s a deliberate, data-backed process that demands rigor and experience.

Let’s walk through how the best in the business get it right – from identifying the right players to keeping relationships productive once the ink dries.

Why Vendor Selection Matters So Much in Heavy Industry

Heavy industry moves on large-scale machinery, raw materials, energy, and expertise. If one link in the supply chain fails, the fallout can be immediate and painful.

Research in the iron and steel sector has shown that three things stand out when evaluating vendors: product quality, delivery compliance, and price. In that order.

Fail on any of those and you’re looking at operational chaos. For instance, if a steel supplier misses a scheduled batch by even a few days, a construction site may halt work entirely – leading to penalties, worker idling, and client frustration.

In manufacturing, defective parts from a single batch can lead to production shutdowns or even safety recalls. In mining or energy, unreliable service partners can introduce serious compliance risks.

So the goal is clear: find vendors who don’t just meet minimum specs but who can handle scale, timelines, and evolving demands without letting anything slip.

A Step-by-Step Vendor Selection Process that Works

1. Define Exactly What You Need

Start with a clear picture of what you’re sourcing. Don’t just list the product – outline specs, volumes, frequency, tolerances, and timing. Think in real-world terms.

- If you’re sourcing drill bits for deep-shaft mining, consider geological demands and lifespan under high torque.

- If you need a crane vendor for a construction project, look at availability, crew qualifications, and turnaround for repairs.

Factor in seasonal cycles, potential project expansions, and applicable regulations.

In mining, that might mean safety standards for dust control. In energy, emissions compliance could dictate who qualifies.

2. Identify and Pre-Screen Candidates

Cast a wide net, but keep it focused. Look for suppliers who already have a track record in heavy industry or similar high-stakes environments. Sources to consider:

- Internal approved vendor lists

- Referrals from trusted peers

- Databases like Thomasnet or sector-specific networks

- Trade shows and industry associations

Don’t skip informal intel. A candid call to a contact who’s used the vendor can reveal whether the glowing case study on their website holds water – or whether you’d be better off checking other suppliers and Hubtrac products from Austria.

3. Build a Heavy Industry-Specific Evaluation Framework

What works for consumer goods or office supplies won’t cut it here. You need to weigh factors that matter when there’s millions of dollars or safety compliance on the line.

A study in the iron and steel industry ranked criteria by importance. Here’s how it breaks down:

| Criteria | Weight | Rank |

| Product Quality | 0.293 | 1 |

| Delivery Compliance | 0.244 | 2 |

| Price | 0.228 | 3 |

| Production Capability | 0.117 | 4 |

| Technological Capability | 0.106 | 5 |

| Electronic Transaction Capability | 0.005 | 6 |

| Financial Strength | 0.006 | 7 |

Notice how quality and delivery lead – price matters, but it’s not the top priority. You might also add:

- Regulatory Compliance (OSHA, EPA, ISO certifications)

- Sustainability practices

- Warranty and service options

- Geographic proximity or local presence

Create a weighted scorecard so you’re not relying on gut instinct. It gives everyone on the procurement team a shared view of priorities.

4. Send Out RFPs or RFQs That Are Actually Useful

Make sure vendors know what they’re quoting on. Spell out:

- Detailed specs

- Required certifications

- Delivery schedules

- Volume expectations

- SLAs (service level agreements)

- Evaluation and scoring method (transparency matters)

The more precise you are, the better you can compare apples to apples.

And vendors who can’t follow instructions here probably won’t handle complex production or logistics either.

5. Vet Vendors Thoroughly

Don’t skip due diligence, even if someone comes with glowing referrals. Key steps:

- Review their financials (you want stability, not surprises)

- Check client references

- Look at past compliance or safety violations

- Visit the facility if it’s a major supplier

- Use vendor management tools or platforms for automated scoring

If the order is large or highly technical, schedule demos or site visits.

Get your engineering or operations leads involved. They’ll often spot risks others miss.

6. Negotiate With Precision

Once you’ve picked your finalists, start the negotiation phase. Look beyond price:

- Can they lock in rates for a longer contract?

- Do they offer volume discounts?

- How will delays or defects be handled?

- Are there penalties for missed deadlines?

A vendor with a strong operational setup will be open to performance-based incentives or penalties.

That’s a good sign they trust their process.

7. Formalize Contracts and Onboard Smoothly

Get everything in writing, down to the last delivery checkpoint and payment term. Include:

- Scope of work

- Service levels

- Response times

- Termination clauses

- KPI definitions

Assign a relationship manager and schedule onboarding sessions with procurement, logistics, and relevant departments.

A few upfront hours here can prevent months of confusion later.

Beyond the Basics

Let’s break down a few of the heavy-hitters in more detail.

Product Quality

In industries where safety and durability come first, quality isn’t negotiable.

A single flaw in a turbine blade or welding rod can create a chain reaction of failures. Always ask about:

- Certification (e.g., ISO 9001)

- QA/QC processes

- Return/rejection procedures

- Batch testing results

If they don’t have data, they don’t have discipline.

Delivery Compliance

You don’t want a vendor who “usually” ships on time. You want one with hard numbers, a solid logistics chain, and redundancy built in. Ask for:

- Historical on-time delivery rates

- Buffer stock policies

- Regional warehouses or depots

- Backup transport partners

Late deliveries affect more than schedules – they tie up labor, idle machines, and kill cash flow.

Production and Technological Capability

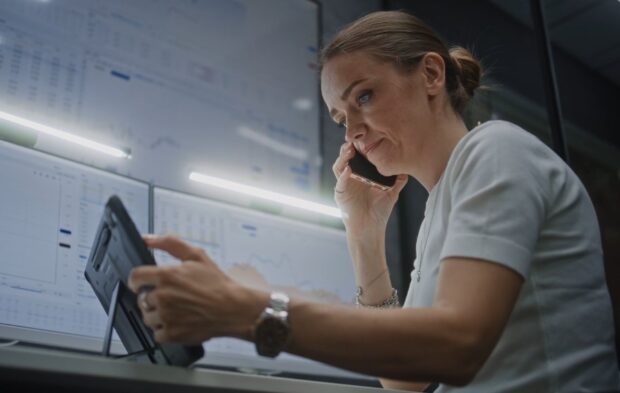

Can they handle a surge order? Do they use tech that gives you visibility? Look for:

- Real-time tracking tools (IoT-enabled systems)

- Customization ability

- ERP integration

- Preventive maintenance programs on service equipment

Technology is your friend here. It gives you clarity and reduces surprises.

Regulatory Compliance and Ethics

Ask about:

- OSHA training

- Environmental risk plans

- Fair labor certifications

- Hazardous materials handling

You don’t want a PR crisis or regulatory fine because a vendor cut corners you didn’t ask about.

How Top Firms Build Long-Term Vendor Success

Heavy industry relies on relationships, not just transactions.

Treat vendors like partners, and you’ll see the results in uptime, flexibility, and responsiveness.

Set Up Regular Check-Ins

Quarterly reviews can include:

- Performance metrics

- Cost trends

- Innovation opportunities

- Problem areas and solutions

Share Forecasts

Give vendors visibility into your demand so they can plan inventory, capacity, and staffing.

In return, you’ll get better pricing and faster response when things change.

Use Scorecards

Track things like:

- Quality defects per batch

- On-time delivery percentage

- Incident or compliance flags

- Responsiveness to service calls

It’s easier to manage what you can measure – and it helps spot problems before they escalate.

The Role of Technology in Vendor Selection and Management

在 Instagram 查看这篇帖子

Digital tools are changing how heavy industry vets and manages vendors.

What’s Working

- AI-powered procurement platforms speed up evaluation

- E-Procurement systems streamline RFPs and contract workflows

- Vendor dashboards show real-time performance metrics

- Risk scoring tools identify hidden red flags early

According to McKinsey, companies using advanced procurement analytics have reduced supplier onboarding time by over 60% and cut costs by 8 to 12 percent.

Staying Ahead

Pressure is growing for heavy industry to clean up its act. That extends to vendors. More firms now screen for ESG alignment. Look for suppliers who:

- Use renewable energy

- Offer recyclable or low-emission materials

- Track their own carbon footprint

- Treat workers fairly and ethically

It’s not just about optics – regulators and investors are watching too.

Vendor Selection in Electronics Manufacturing

A global electronics firm needed a vendor for ASIC chips – a critical, high-cost component with tight delivery requirements. The process:

- Cross-functional team (engineering, procurement, finance)

- E-procurement system to issue RFPs and rank responses

- Scoring based on technical fit, financial health, and ESG alignment

- Negotiated volume discounts and priority scheduling

- Required ISO 9001 certification and documented QA process

The result? Zero delivery delays and a 15% cost saving in the first year.

Summary

Vendor selection in heavy industry isn’t a one-size-fits-all exercise. It’s a high-impact decision that shapes the performance, safety, and profitability of every project.

By putting structure around the process, focusing on what really matters – and treating vendors like partners, not just line items – you set yourself up for smoother operations, better outcomes, and fewer emergencies down the road.

Bring in the right partners, and the job just works better.

Jewel Beat

Jewel Beat